Fire Suppression Systems Sales, Service, Maintenance and Testing

Restaurant Kitchen Hood Suppression Systems

Fire Suppression Services

- Kitchen hood suppression system semi-annual test and inspection

- Fusible links

- Dry chemical suppression system

- Hydrostatic test of low pressure cylinders

- 6-year internal maintenance of low pressure cylinders

Factory Certified

- Ansul

- Firelite

- Heiser Logistics

- IFC

- PyroChem

- Silent Knight

References

References are available upon request.

Fire Alarms

ADI International

Our affiliation with ADI International enables us to offer a complete line of electronic security and low voltage products including Firelite and Silent King.

Brooks Equipment Company, Inc.

Our affiliation with Brooks Equipment Company, Inc. enables us to offer a complete line of Life Safety products.

- Fire Alarm Products

- Fire Extinguishers, Chemical, & Parts

- Fire Hose, Nozzles, Brass, & Hose Valves

- First Aid Products

- Kitchen Hood & Restaurant System Parts

- Safety Products & Service Equipment

- Sprinkler Accessories & Standpipe Equipment

- Cabinets, Accessories, & Covers

- Signs, Labels, Exit & Emergency Lighting

Winnelson Fire Supply Reliable

Sprinkler Strategic Partner

The Fire Alarm Control Panel (FACP)

“A Fire Alarm Control Panel, also referred to as a Fire Alarm Panel or FACP, normally referred to as a Panel within the fire protection industry is a central control device for detecting, reporting and acting on occurrences of fires within a building. There are two types of panels: conventional panels, and analog addressable panels.

In a conventional panel, fire detection devices including, but not limited to smoke detectors, heat detectors and manual call points or manual pull stations are joined up with a number connected to each circuit. When a device on the circuit is activated, the panel recognizes an alarm on that circuit and could be set up to take a number of actions including directly calling the fire department via an alarm transportation system (ATS).

An addressable panel is a more modern type of panel, and has greater flexibility than a conventional panel. An addressable panel has a number of loops, where a number of devices are able to be connected, each with its own address. There is no standard protocol as such, and thus a number of proprietary solutions exist. Loop devices have traditionally been able to have 99 or 100 devices connected, but more recent protocols allow many more. This is usually overcome by having multiple loops on one system.

Fire panels are required in the Building code for new structures in most countries.”

“Fire alarm control panel.” Wikipedia contributors. Wikipedia, The Free Encyclopedia

Related Wikipedia links

Technical Manuals for Fire Alarm and Security Alarm Systems

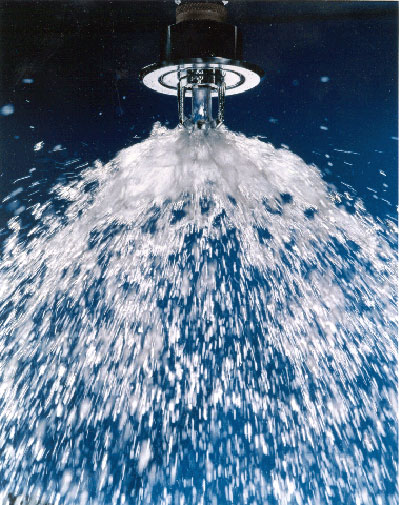

Fire Sprinklers

Fire Sprinkler and Fire Pump System Testing, Inspection, Modification, Relocation, Tenant Finish and Maintenance

We test and inspect fire sprinkler systems in accordance with NFPA 25. Annual testing of your fire sprinkler system is required by local fire code and more frequently by some insurance companies and state agencies. Our technicians can inspect and service all types of sprinkler systems. We can also provide training in the proper use and maintenance of your system. We strive to work as a team in maintaining your building’s fire suppression sprinkler system in order to provide the best operability of your fire sprinkler system to ensure that it works as it was designed and installed.

Test & Inspection

An inspection is a visual examination of a water-based fire protection system, or portion thereof to verify that it appears to be in operating condition and is free of physical damage. Testing is a procedure to determine the status of a system by conducting physical checks on water-based fire protection systems such as water-flow tests, fire pump tests, alarm tests, and trip tests of dry pipe, deluge, or pre-action valves. These tests follow up on the original acceptance test at intervals specified in the appropriate chapter of the standard NFPA 25. We perform these duties on a schedule determined by you the customer, the local Authority Having Jurisdiction, also known as AHJ, and applicable codes.

Flow Test

- Underground and Exposed Piping Flow Tests. Underground and exposed piping shall be flow tested to determine the internal condition of the piping at minimum 5-year intervals or at an interval specified by your local AHJ.

- Flow tests shall be made at flows representative of those expected during a fire for the purpose of comparing the friction loss characteristics of the pipe with those expected for the particular type of pipe involved, with due consideration given to the age of the pipe and to the results of previous flow tests.

- Any flow test results that indicate deterioration of available water flow and pressure shall be investigated to the complete satisfaction of the authority having jurisdiction to ensure that the required flow and pressure are available for fire protection.

- Where underground piping supplies individual fire sprinkler, standpipe, water spray, or foam-water sprinkler systems and there are no means to conduct full flow tests, tests generating the maximum available flows shall be permitted.

Backflow

- T&I Repair & Install

- ASSE & IAPMO Approved

Colorado Alarm & Fire Protection

- State of Colorado Registered

- Fire Suppression Systems Contractor: 20-S-10045

- Fire Suppression Systems Contractor Backflows: 20-S-07483